Turbulent flow

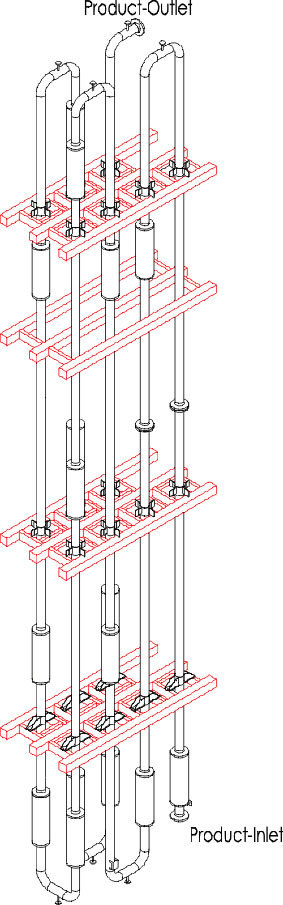

Static Mixer with elements - Type AGENS® AMV

Dispersing of low viscous liquids/ gases

The AGENS® AMV Mixer bonds insoluble fluids to each other in a continous current. The disperse phase leaves the mixer as a droplet or bubble cluster. The smaller the generated droplets or bubbles, the larger the interphase boundary. The hydraulic diameter of the built-in components thus has high significance.

Advantages of the AGENS® AMV structure• The hydraulic diameter can be precisely adjusted by determining Additional Typical Applications • Hydrocarbon neutalization • Phosgenation of bisphenol • Chlorination • Hydrogenation • Air, CO2, O2 or ozon in drinking water

|

|